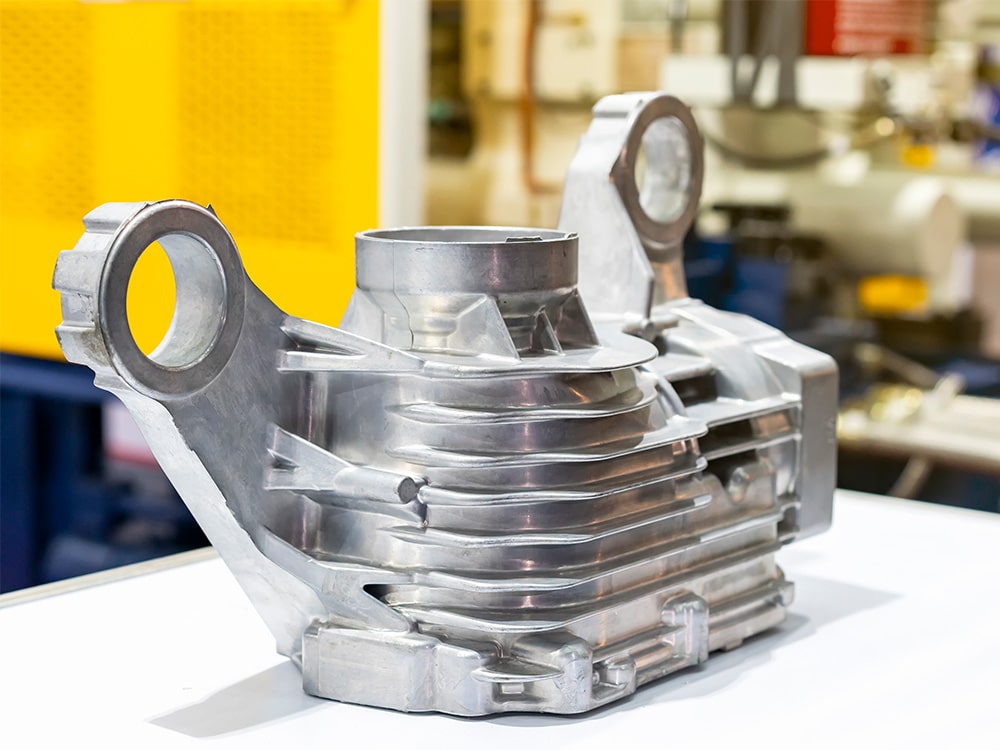

Aluminum Die Casting

FG MFG with their partners offer Aluminum die-casting services tailored to your specific project needs. With our advanced facility and experienced team, we consistently deliver high-performance parts.

Advantages of Aluminum Die Casting:

- High Precision: Capable of producing parts that are corrosion-resistant with complex geometries

- High Production Rate: The process can be highly automated and is suitable for high-volume production.

- Strength and Durability: Die-cast aluminum parts are strong, durable, and have a good weight-to-strength ratio.

- Surface Finish: Produces parts with a good surface finish, often requiring minimal additional finishing.

Aluminum die casting is widely used across various industries due to its efficiency, cost-effectiveness, and ability to produce high-quality parts for the following applications:

Vehicle: Engine components, transmission parts, structural elements, wheels and suspension

Aerospace: Aircraft engine parts, structural components, housings, missile and rocket parts

Weapons and Ordnance: Gun components, castings, and other components for various types of munitions

Consumer Electronics: Device housings, enclosures, frames, and heat sinks

Industrial Equipment: Machinery, tools, pump housings, motor casings, and gearboxes

Medical Devices: Diagnostic equipment, surgical instruments, and imaging components

Ready to talk about your Aluminum Die Casting needs?

Request a quote